FIELD HANDLING TECHNIQUES FOR EPOXY-COATED STEEL REINFORCING BAR

Just like any material used on a job site, appropriate handling of Epoxy-Coated Rebar is required. These steps are aimed at reducing damage to the bars that would reduce the effectiveness of the coating to perform and provide long-term protection.

Basic guidance steps for correct field handling of epoxy-coated steel reinforcing bar prior to or during casting :

LOADING & UNLOADING

Bundle by bundle of coated bars are to be removed from Trailer without dumping them on in the ground. They have to be carried by workers and then put down carefully at stacking place

Epoxy-Coated Steel Reinforcing Bars should be lifted using a spreader bar or strong back with multiple pick-up points to minimize sag.

Cloth Belts, Nylon or padded slings should also be used.

DO NOT use bare chains or cables.

STORAGE

Coated bars to be placed over a covered surface and not on the ground. As in the case of stacking on the trailer the bars are placed layers by layer separated by wooden spacers. Then they are covered with covers with holes to avoid condensation.

Store bundles of Epoxy-Coated Steel Reinforcing Bar on suitable material, such as wooden dunnages.

If the Epoxy-Coated Steel Reinforcing Bars are to be exposed outdoors for more than 30 days, cover with a suitable opaque material that minimizes condensation.

Store coated and uncoated bars separately.

BENDING

The coated bar whether it is bent using bending machine or bending pin sufficient precaution there should be taken for avoiding rubbing of coated bars against the metal of bending equipment. In case of bending machine, the mandrel should be covered with PVC cover.

If a crowbar is used for bending, it should be plain pin and not the ribbed bar and it should be covered with a sleeve. The surface on which coated bar is placed for bending should be smooth.

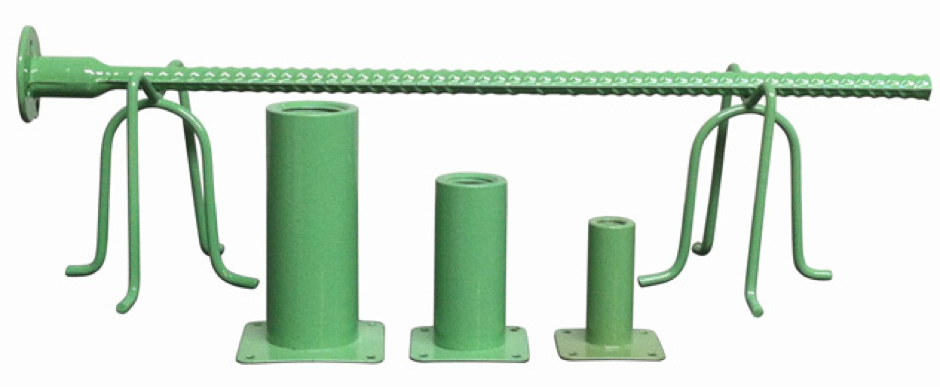

BAR SUPPORTS

Use bar supports coated with a non-conductive material or plastic bar supports.

PVC COATED BINDING TIE WIRE

Use a coated tie wire for securing Epoxy-Coated Steel Reinforcing Bars.

The PVC coated binding wires should be used instead of GI wire for binding the coated bars to avoid damage to coated bars. The binding over the bar should be just sufficient, should not be too lose or too tight.

TOUCH-UP COMPOUND PATCHING

WELDING

Even though the coating is insulated, welding can be done by removing a very small area of coating to allowing current to pass through or welding. After welding the area of welding can be cleaned and patched up.

CUTTING

The cut ends are to be touched up in the patch-up compound, liquid epoxy patch up the compound, one resin two component and another hardener. Where ever damages are there while handling cutting bending wielding, the damaged area should be prepared immediately.

The application of the patch up is in the patch up compound executed by mixing of hardener and resin in a recommended proportion.

All damage (cut ends, cracks and abrasions) should be patched using a two-part epoxy repair material, approved by the coating manufacturer. Follow manufacturer’s directions.

CONCRETE VIBRATION HEADS

Use a plastic headed vibrator to consolidate concrete. This will avoid direct contact with the Vibrating head to the coated bars getting hammering effect.